Coupon ???? Design Engineering 010003 Black Titanium 2″ X 50′ Exhaust Heat Wrap With LR Technology ????

$54.49 Original price was: $54.49.$38.14Current price is: $38.14.

- Have the best deals

- Experience Quality, Shop with Us

- Shop with confidence, we guarantee quality.

- Experience the difference quality makes.

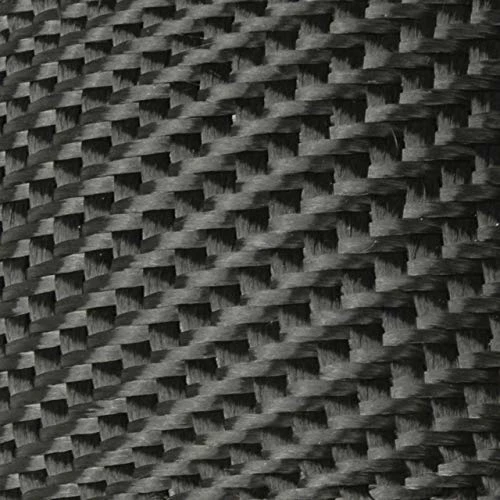

The DEI Titanium Exhaust Wrap, with LR Technology, is made from pulverized lava rock, stranded into a fiber material then woven into a proprietary weave. Titanium wrap is engineered to be stronger than most wraps and more durable for improved thermal performance and reliability.

- Titanium wrap is engineered to be stronger than most wraps and more durable for improved thermal performance and reliability

- Withstands 1800 degrees Fahrenheit direct heat and 2500-degree intermittent heat

- Promotes increased flow for improved performance; reduces temperature & vibration breakdown

- Extremely pliable for a tight and secure wrap

- High resistance to abrasions, oil spills, temperatures and vibration breakdown

- Fit type: Universal Fit

| Size | 1" x 15', 1" x 50', 2" x 15', 2" x 25', 2" x 33', 2" x 50', 2" x 50' (Smaller Packaging), 2" x 100', 4" x 100', 6" x 100' |

|---|---|

| Color | Titanium, Black Titanium |

8 reviews for Coupon ???? Design Engineering 010003 Black Titanium 2″ X 50′ Exhaust Heat Wrap With LR Technology ????

Add a review Cancel reply

Related products

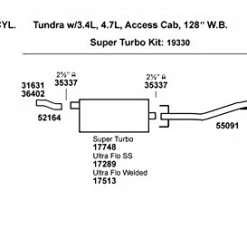

Exhaust Systems & Parts

Exhaust Systems & Parts

Exhaust Systems & Parts

Exhaust Systems & Parts

Flash Sale ???? EX-2012 Stainless Steel Oval Slant Cut Bolt-on Exhaust Ti ????

Exhaust Systems & Parts

Exhaust Systems & Parts

Exhaust Systems & Parts

Best deal ???? 134-1202 Chromoly Header Bolt Kits, Chevrolet Gen III/LS Series, 3/8˝ Wide ????

Exhaust Systems & Parts

Gregory Muncer –

Hi FolksGreg Muncer here with Advanced Fleet Specialists of 37 years.I have a 1988 Chevy Caprice that is in great shape.The exhaust pipes and muffler needed 6 repairs.I search this product down;not wanting to replace the exhaust system.I followed every direction and added these things.1) I scrubbed an area around the repairs about a third away around the pipes,with a stainless steel wire toothbrush, and with Clorox Clean Up (spray) anda spray water bottle to thoroughly rinse the area after the wire brush and soapy bleach scrubbing.Then I quickly wipe the area mostly dry with a paper towel so it did not flash rust much.2) I tape measured the repair area to make a patch about an inch longer than the ends of the repair area.3) I bought off Amazon here, one roll of ” DEI 010129 2″ Titanium Exhaust/ Header Wrap – 15′ ” for $14.95.This 2 inch wide exhaust wrap was a dog’s great fetch, (“a cat’s meow” ha ha),I took the Muffler Putty ” Permatex 80333 Muffler and Tailpipe Putty – 4 oz. ” , available here on Amazon also,and needed it (which mixes it just prior to use), like the directions said.I screeded the packet to the edge where you cut the packet open, then I cut only about 1/3 the end off,to be able to squeeze out about a 1 inch wide squeeze out of the packet.I squeezed the putty onto the measured and cut exhaust wrap mention above.I squeezed the putty onto the middle of the 2 inch wide tape all along its length.I then took a stiff piece off plastic, for a putty knife andsmoothed the putty over the tape, covering every edge.(I had laid the tape on a cardboard box to dispose of the mess made on a workable disposable surface)So, spread the putty thoroughly a little less than 1/4 inch thick on one side of the tape.4) With the tape spread with putty, I took my water spray bottle and wetted the repair area again.This time I only dried it very lightly, leaving it wet but not dripping.I dabbed up the drips with a paper towel.I then place the putty side of the tape against the wire brushed and wetted repair area;where the puttied tape patch, hung over the repair area about an inch on each end.I used disposable latex gloves and so with these gloves on,I smoothed the outty all over the tape which brought some of the extra putty to the edges of the tape.While smoothing the tape out, I had some putty come through the tape that is a little pores.(Careful to leave the center of the tape humped up a bit on its center length,so as to leave a good thickness of putty over the holes in the pipe or muffler).Extra putty from the packets can also be used over the outside of the tape to seal up the pores tape.Smoothing over the complete tape patch and its edges with putty makes a smooth cast like product,just like a cast use for a persons broken arm, except this cast is good for extremely high heat.5) Once you get your patch smoothed out on the repair area,I set a 1500 watt (small heater withing an inch of the surface of the wet patch.I found that the patch had to stay as hot as this heater would make it, for at least an hour or longer is better.(I had one place that I could not get the heat close enough to make the pipe hot for an hour and,when I drove the car (without giving it much gas) the patch had not sufficiently hardened andthe path lift off one end and the exhaust was escaping out the repair hole again)>Point is make sure you heat the patch good for at least about an hour.I found the heater made the patch and pipe hot enough that you could still touch it without burning your hand but,probably you could not leave your hand on the hot patch more than a few seconds without burning your hand.This should give you a good idea as to how hot to make the patch.It could even be a little hotter than this, although I like a slower curing process so,that it does not bubble up from too quick of hot heat causing the putty to boil before it hardens.Keep in mind that this tape over the putty slowes down the drying process andso the heater and the whole hour heating the patch seems to become absolutely needed.In summary this is a fantastic product and the tape really helps to bridge the gaps and maintain a real good consistent thickness of the repair.I used 3 packets out of the 4 packets that I bought.(Each of these purchase packs contained 2 packets inside each pack, soI used 6 little packets altogether.)Each tape patch average about 8 inches long and was applied long ways onto the pipe.I did not wrap the tape patch around the pipe except for one of the repairs that required it.The 2 inch wide tape came in a 15 foot roll and I used a little less than 5 feet of it.I paid $3.40 a pack and used 3 packs so I used about $10 bucks of putty and $5 bucks worth of the tape; soI used $15 dollars of product to make 6 beautiful patches. (I wasted some, when I did not let the one patch heat up hot enough and long enough).Use a heater, wire brush the area and get any greese off the repair area with a soapy bleach. Rinse it well with water (the putty is water based),pre wet the repair area just before applying the wet patch.My exhaust system was strong before I began and was being held firmly by all connections and exhaust hangers, but every pipe, muffler and resonator require a sizable patch and so it this $15 bucks worth of muffler putty and 2 inch wide tape save me the best part of $1,000. I feel confident I will not have to replace this exhaust system for another few years. Thank You Amazon, Permatex and Design Engineering; maker’s of the 2″ Titanium Exhaust/ Header Wrap – 15′.Happy Motoring, Sincerely Greg (I still spent 6 hours repairing the 6 areas) but just paid $15 bucks.Both these products, the putty and the tape were good up to temperatures of 2,000 degrees, oh yea.

Michael P –

READ THIS PLEASE: I purchased a $400 Winnerwell Woodland Large wood stove with a 3.5” flue pipe. To use it in a hot tent with a stove jack, I decided to research the latest high-tech heat shields that would reduce significantly the heat radiated from the 16-inch flue pipe that goes through the stove jack. This mod was intended to greatly reduce the fire hazard and possible damage to the tent fabric adjacent to the jack panel where the pipe passes through. The cooler the pipe wall, the less stress and heat transferred to the jack outlaying tent fabric.I discovered on Amazon a product by Design Engineering #010127 Titanium 2″ Exhaust Heat Wrap with LR Technology. Their ad states it can withstand temperatures up 1800°F — which was impressive and seemed like a candidate to be wrapped around the 3.5” pipe going through the stove jack, reducing the exterior surface of the pipe in contact with the silicone jack boot. I phoned Design Engineering in Ohio and explained my project to get their opinion on the efficacy of my theory using their heat wrap. They confirmed it would work as I expected, since they claimed to have used it on exhaust manifolds to trap the inside the pipes to increase exhaust efficiency. So, I bought it and tested it. Then came the rude disappointing surprise.I placed the pipe section with the double-wrapped heat-wrap at the third section of the pipe stack above the stove’s hot box, and fired up the stove — with the wrapped pipe at about the right height if it were feed through the stove jack. With my digital infrared thermometer, I checked the temp at the rear of the hot box (where it reaches the hottest temps), then the first pipe, second pipe, and finally the heat-wrapped pipe at the top of the stack.Well, from the tone of this review, you’ve likely guessed the results. The third heat-wrapped pipe was significantly hotter than the pipe below it. Since the pipe below the wrapped one was closer to the hot box, you would expect it to be much hotter. But NO. It was significantly cooler. I checked the stack’s temps over and over to make sure there was no mistake in taking the temperature readings. The only conclusion I could reach was that its main ingredient is Basalt, which is impregnated into the weave of the fabric, and was actually holding the heat instead of blocking its transfer from the flue pipe. Else why it be hotter than any of the other pipes in the stack, especially when it was farthest from the hot box than the other pipes? And to matter worse, at one point the testing, I noticed smoke being emitted from the titanium wrap, at which time I dampened the fire to prevent any flare ups.This product may be effective for exhaust manifolds, but it definitely is NOT proficient at blocked heat from passing through it with stove pipes. It seems better at retaining heat instead of blocking or dissipating it. The DEI packaging claims the wrap “Reduces under-hood temperatures up to 50%.” I find that hard to believe since in my testing the wrap became hotter than the pipe it was supposedly shielding.I was intrigued with the results of my testing and decided to research Basalt (the main active ingredient in the DEI heat wrap). The research disclosed the basalt glass possesses excellent heat storage capabilities — meaning it can be used to retain heat instead of shielding against heat sources. Well, this explains what happened in my testing. The basalt in the wrap was actually accumulating heat and retaining it — which explains why it was hotter than the pipe surface it wrapped around. Science says that this heat-wrap tape actually performs quite the opposite of what DEI contends it should be used for.The following is a direct quote from a research study found on the internet: “In summary, compared with other sensible heat storage materials, basalt glasses studied in this work not only have the characteristics of low cost and being environmentally friendly but also have higher heat capacity, thermal conductivity, and excellent thermal stability between 100 and 1000 °C. Moreover, it has been concluded that these basalt glasses are suitable candidates for concentrated solar power plants and home heating systems.”Basically and definitively, this scientific study has shown that the basalt used in this heat-wrap has better characteristics for “accumulating and storing” heat than it does in shielding heat for protection to the touch. For this alone, it is a very poor choice for insulating a stove flue pipe when used in a hot tent scenario. It does NOT shield the heat, but rather accumulates and stores heat in increasing degrees.And the “1000 °C” figure quoted in this scientific study also coincides with DEI’s claim that their wrap is rated up to 1800°F (which equals 1000 °C). Check the internet to verify these scientific research facts for yourself.I urge Amazon customers to AVOID using this very expensive heat wrap to reduce the outer surface temperature of a stove pipe or similar heat producing object. It gets hotter instead of cooler. Go figure.

David Preston –

I’ve wrapped 1 Turbo header and by the time I was 1/4 of the way into it I was itching like I had been messing with fiberglass. I bought this specifically because it stated to be made with the LR technology and not Fiberglass. Inlaid more for this product because I didn’t want to deal with the Fiberglass issues.

Gonzo –

I recently built my Mazdaspeed 3 and with the new headers I was getting a lot of heat under the hood, like extreme heat. Bought this wrap hoping to contain some of this furnace emanating from the header. My wife and I, yes my wife who is more mechanical than pretty much all of the “guys” I know, wrapped each header tube per the instructions. Be ready to bath in fiberglass cause it gets everywhere BUT this wrap dropped my under hood temps by about 30-40°. Looks great and works really well. If you’re having temp issues from exhaust this is a must have.

ShirinGasai –

remember to order the correct size for your application

Amazon Customer –

Great product

Jed Webster –

Haven’t used it yet- just wanted to leave a review to say don’t assume they come with the binding straps like i did. You have to order those separate. Cheers

Richard –

Durability and heat dispersion are great I give it five stars…only thing is the color faded alittle faster than I hoped but I don’t blame it when it’s on a piece of metal that constantly gets to 800+ degrees, 5 STARS!!!