Brand new ❤️ Mr. Gasket 77 Exhaust Gasket Performance Material ????

$6.47 Original price was: $6.47.$4.53Current price is: $4.53.

SKU: AMZ-B000BWCEYM Category: Gaskets

- Have the best deals

- Experience Quality, Shop with Us

- Shop with confidence, we guarantee quality.

- Experience the difference quality makes.

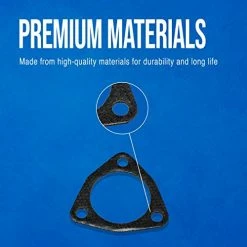

Mr. Gasket Exhaust Gasket Material enables you to build your own infinitely customizable gaskets. Made of a heat-resistant, tear-resistant compressed-fiber laminate that can be trimmed into any configuration to meet your exact specifications, it comes in a 1/16-inch-thick 10×10-inch square.

- Enables you to build your own infinitely customizable gaskets

- Made of a heat resistant tear resistant compressed fiber laminate

- can be trimmed into any configuration to meet your exact specifications

- Comes in a 10 inch by 10 inch square

8 reviews for Brand new ❤️ Mr. Gasket 77 Exhaust Gasket Performance Material ????

Add a review Cancel reply

Related products

Sale!

Rated 4.57 out of 5

Sale!

Rated 4.29 out of 5

Sale!

Rated 5.00 out of 5

Sale!

Rated 4.14 out of 5

Sale!

Rated 4.43 out of 5

Sale!

Sale!

Rated 4.43 out of 5

Sale!

Rated 4.29 out of 5

Charles Wadsworth –

I haven’t had this material long enough to rate its actual performance. It seemed to seal alright, but over time … ‘Can’t say. What I do want to do here is give advice. This stuff isn’t easy to cut to shape, at least not smaller O-ring shapes, because the metal mesh sandwiched inside is so much tougher than the relatively flakey composite that the composite breaks up before you can cut the mesh. I have found one very good method that works. I used an electronic nibbling tool sold for nibbling out various shapes in electronic chassis and covers. It just ‘bites’ off pieces. I also suspect that an abrasive bit, perhaps a diamond bit in a rotary tool might work well. Several attempts I made to use a spade bit, router or snips just wouldn’t work, they wound up spoiling the material. I tried a cold chisel and also ruined the piece. Abrasion that won’t grab is better, or the nibbler that provides a kind of anvil to back it and snap off a piece seemed to work best. I had no trouble smoothing the outer edges of an O-ring shaped piece on a bench grinder as long as I kept the edge parallel to the rotation of the wheel. Used sideways it tended to knock the composite off in chunks. The stuff certainly saved my day as the gasket I needed is unavailable and in any event would have cost much more.

FC3 –

I recently put my 1983 Imperial back on the road. One of the things that needed to be fixed was the air injection tube that feeds air from the air pump to the back of both exhaust manifolds. The original tube was burned out and could not be repaired. And replacements are not available anywhere. After looking for years, I mentioned the problem at dinner and my brother-in-law, Pete, volunteered to make one for me of stainless steel.The stainless tube fit perfectly, but the OEM style thin paper-like gaskets kept burning out and leaking. I then realized I made a mistake by having the new tube made of stainless. The coefficient of expansion between the stainless tube and cast iron manifold was causing problems. I needed a thicker gasket.Ordered this product. Using my last OEM gasket as a template, I cut two new gaskets and reinstalled the air injection tube. Previously, the OEM style gaskets would last perhaps a couple of days. The gaskets made from this material have not failed or leaked.If you need to make your own gaskets that need a thicker and more resilient material, this works well, even on the exhaust manifold. I very much recommend it.

Sean Williams Brown –

I have made a number of gaskets from this stuff and it seems to hold up very well. I use Ultra-silicone (black or copper) as a dressing, and it holds up good. I think it’s a good value for the money.

RONALD GROHS –

Worked well for what I needed

William R Gr –

didn’t work out too well

Riverwink –

Heavy gasket material worked perfectly. The gasket on our 100 gallon compressor blew out. This works perfectly!

tom fallon –

Yes its gasket material. Work good on my mini bike header.

John Roskoski –

Easy to cut for header flange and collector gaskets. Would purchase again.